The Importance of Modular Design in Today’s Manufacturing

Why flexible, scalable processing equipment is essential for food & beverage manufacturers

The food and beverage manufacturing landscape is evolving at a dizzying pace. Shifting consumer demands, regulatory pressures, labor shortages, and the drive for sustainability are exposing the limitations of traditional fixed-line systems. These outdated setups are often too rigid and expensive to adapt to such fast-moving changes. Modular food processing equipment, however, offers a smarter path forward: it's adaptable, scalable, and built to evolve with the industry.

Why are Modular Systems Critical for Modern Food & Beverage Operations?

Modularity is essential in today’s food manufacturing landscape for several reasons:

#1 Scalability

In the fast-paced food and beverage industry, shutting down production to replace entire systems can be costly and disruptive. Modular systems offer a more efficient solution, allowing manufacturers to increase capacity incrementally without halting operations. This flexibility not only minimizes downtime but also helps companies manage costs more effectively by investing only in what’s needed at each stage of growth. It’s an ideal approach for smaller producers with ambitious growth plans, as well as established facilities looking to expand efficiently without overcommitting resources upfront.

#2 Faster innovation cycles

Modular systems are vital in food product development, empowering companies to efficiently test and launch new products with reduced risk. This approach is particularly effective in fast-evolving categories like plant-based, upcycled, or clean-label foods, where speed to market is essential. By enabling limited-scale rollouts and quick iterations, modular systems reduce development time and support faster innovation cycles—helping brands stay ahead of emerging trends and consumer demands.

#3 Cost and labor efficiency

Thanks to their compact design and high level of automation, modern modular food processing systems require fewer operators to manage daily operations.

This not only lowers labor costs but also minimizes downtime—even as production capacity scales with the addition of more units.

RENU™ Drying & Milling System: Modular Design in Action

The RENU System by GTF Technologies is a powerful, real-world example of modular, scalable design in food processing. RENU delivers measurable results while adapting to a wide range of production needs.

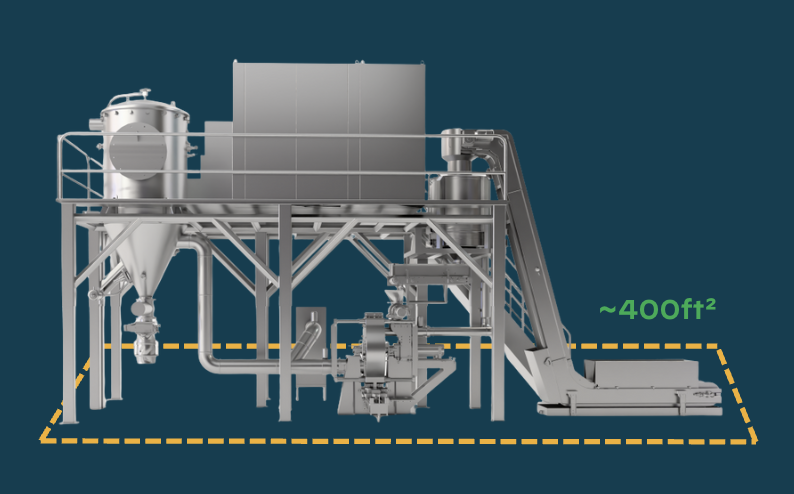

At the core of its modular design is a compact footprint—just over 400 ft² (37 m²)—making it easy to integrate into existing lines or scale up through the addition of multiple units. Each system operates independently or in tandem, enabling processors to grow capacity incrementally, without complete facility makeovers.

Full automation allows a single operator to manage the entire drying and milling process, optimizing labor efficiency. RENU is also fully electric, reducing energy consumption and eliminating dependence on fossil fuels—an essential advancement in an energy-intensive industry.

Every RENU system can be customized to match product needs, output targets, and floor plan limitations. This design flexibility makes RENU especially effective in upcycling food side streams and byproducts into high-value powder ingredients—a modular approach to sustainability and profitability.

By turning waste into revenue and scaling to meet demand, RENU exemplifies how modular design can drive innovation, efficiency, and environmental impact in modern food production.

Modular Design as a Strategic Advantage

Modular design offers more than just technical efficiency—it serves as a powerful strategic advantage in today’s fast-paced and competitive market. With interchangeable, self-contained units, modular design enables faster decision-making, adaptability to shifting market conditions, and the ability to innovate without overhauling entire systems.

This approach allows organizations to make incremental, low-risk investments while scaling operations more effectively. As a result, businesses gain operational resilience and agility, positioning themselves to respond swiftly to a constantly changing landscape and seize emerging opportunities with confidence.

Is Your Equipment Built for What’s Next?

In today’s fast-evolving food and beverage industry, being future-ready isn’t optional—it’s essential. Modular design is at the heart of this transformation, enabling manufacturers to grow, evolve, and stay competitive without rebuilding their infrastructure. GTF Technologies is leading this shift, delivering smart, scalable solutions that empower processors to stay ahead of shifting market needs. Systems like RENU are redefining what’s possible on the production floor—modular, efficient, and built to grow with your business.