Clean Power, Clean Data: How RENU Helps You Thrive Under Cap & Trade

As sustainability regulations tighten, food manufacturers are under increasing pressure to reduce waste, lower emissions, and demonstrate measurable climate impact. One of the biggest opportunities often overlooked is the carbon value locked inside food manufacturing side streams. Instead of sending this material to landfills or low-value disposal pathways, companies can convert it into high-value ingredients—and document significant landfill avoidance along the way.

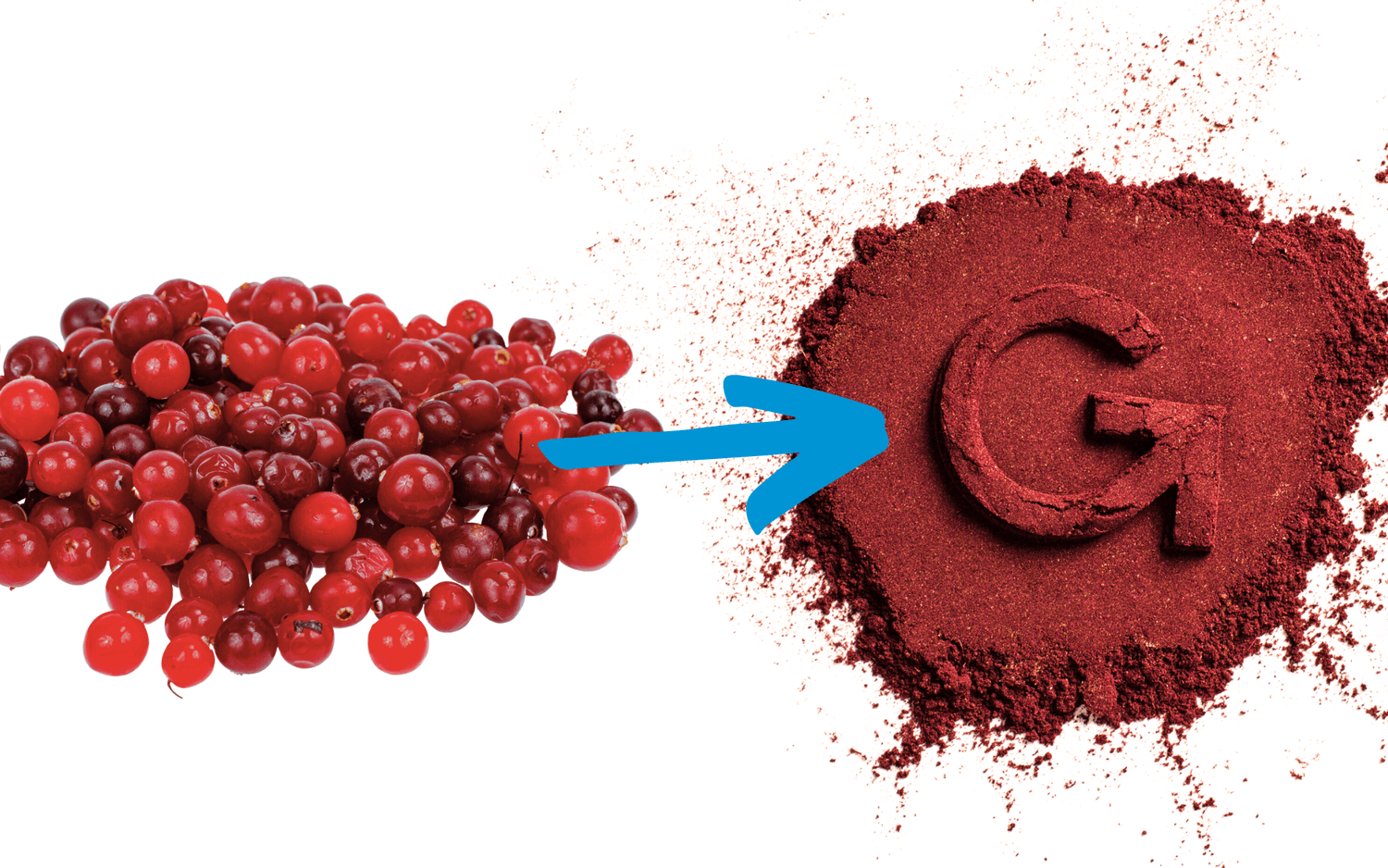

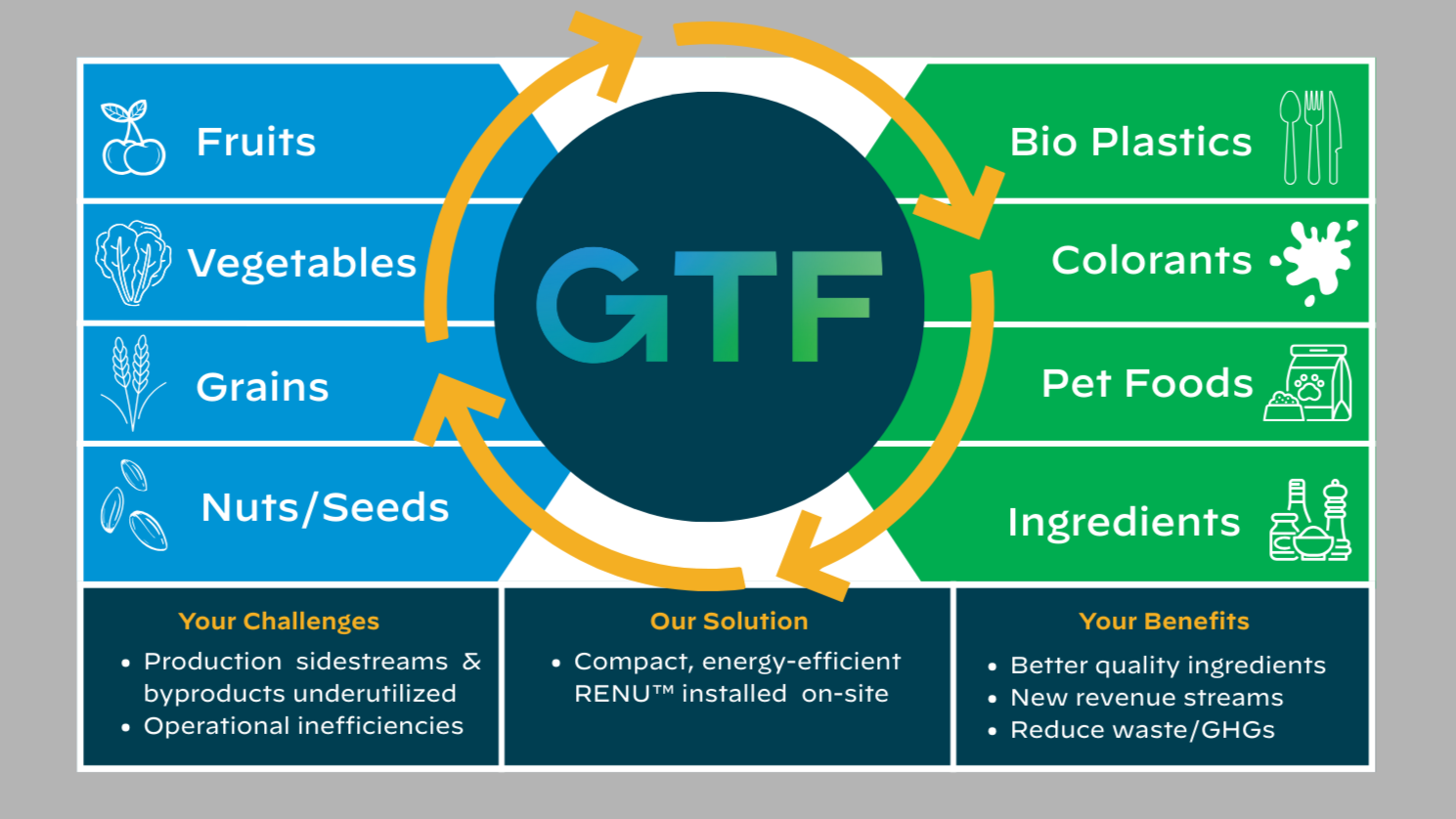

GTF’s RENU™ Drying & Milling System , an all-electric industrial processing technology, powderizes food side streams at the point of generation. By transforming what was once waste into valuable, shelf-stable ingredients, RENU supports circular economy goals, reduces landfill reliance, and creates measurable environmental impact that can be leveraged in cap-and-trade and carbon credit markets.

What the RENU™ System Does

RENU is a system of industrial processing equipment designed specifically for:

Powderizing wet or semi-solid food manufacturing side streams

Stabilizing nutrients and capturing material at peak value

Reducing or eliminating the need for landfill or waste-hauling services for food waste

Mitigating reliance on natural gas for drying

Creating high-value, reusable ingredient powders

Supporting measurable landfill avoidance for ESG and carbon market use

By converting side streams directly on-site—without combustion, gas use, or emissions—RENU gives manufacturers a pathway to zero-waste, low-carbon operations.

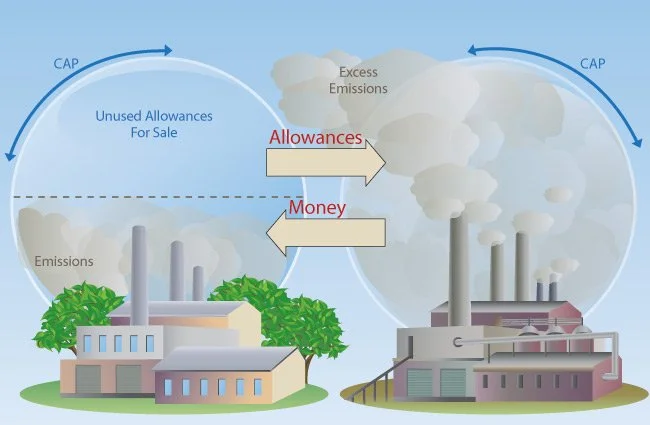

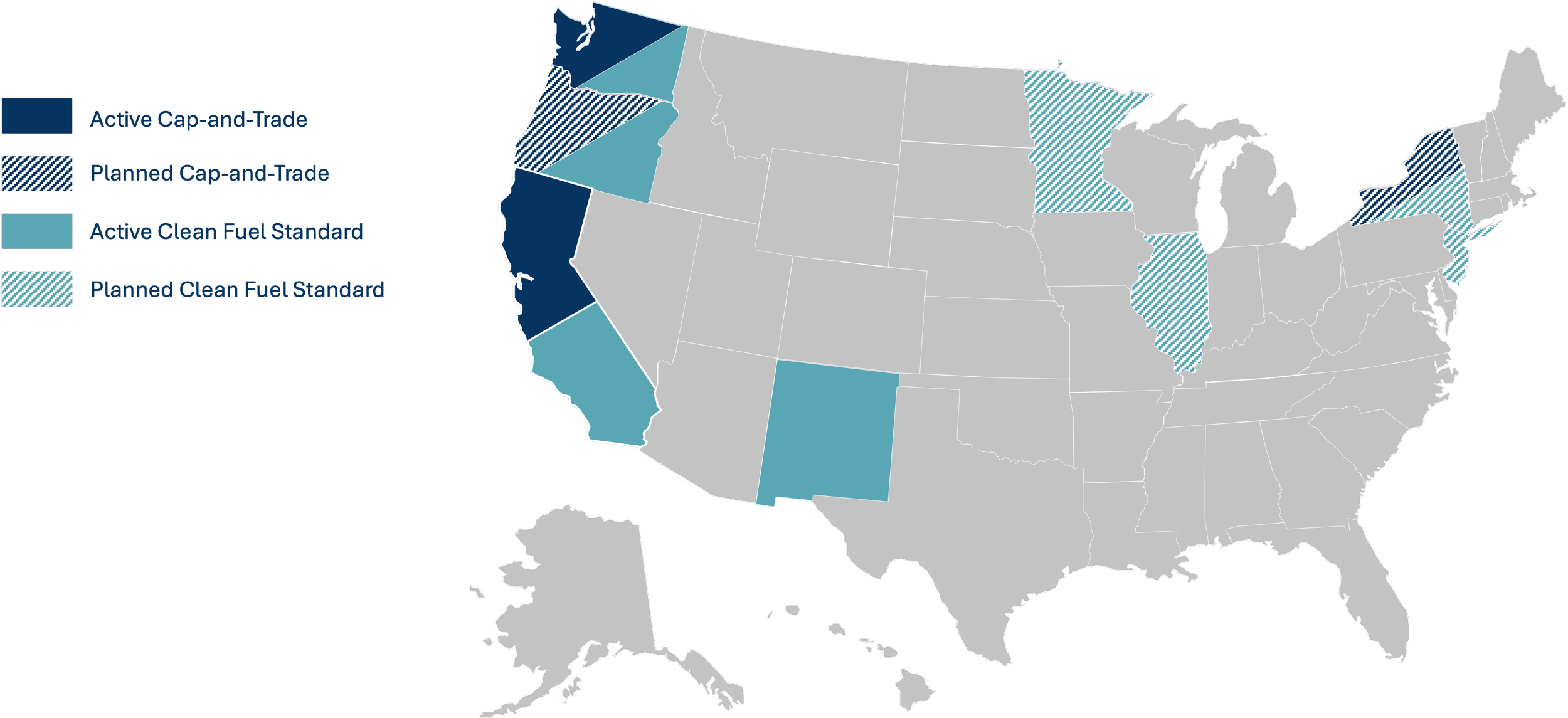

The All-Electric Advantage in Cap & Trade States

In areas where natural gas is regulated under cap & trade, equipment that relies on gas combustion can increase:

Direct emissions

Compliance obligations

Carbon-related fuel surcharges or shutdowns

Exposure to future regulatory tightening

Because RENU operates entirely on electric power, it provides several advantages:

Zero onsite combustion emissions

No direct cap-and-trade compliance requirements

Reduced operating exposure to natural-gas carbon pricing

Alignment with electrification and decarbonization policy goals

This makes RENU not just a sustainability tool, but a regulatory-savvy choice for food manufacturers in regions with strict energy or carbon rules.

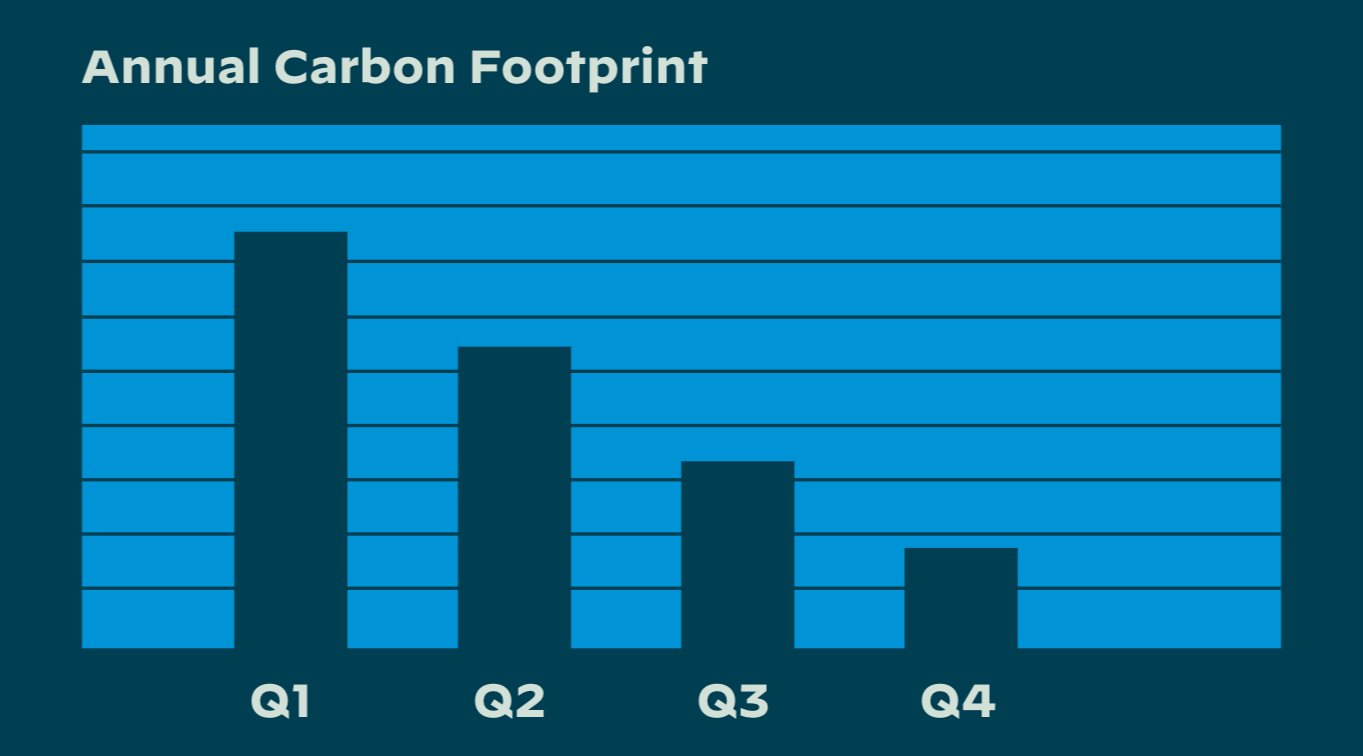

Why Landfill Avoidance Matters in Carbon Markets

Food waste in landfills accounts for 57% of all methane emissions worldwide—a greenhouse gas significantly more potent than carbon dioxide. When manufacturers divert side streams from landfill through on-site powderization, they support:

Methane avoidance

Reduced landfill dependence

Improved waste-management efficiency

Eligibility for certain carbon offset methodologies

Many carbon markets and offset programs recognize the value of waste diversion, material recovery, and methane avoidance, making RENU a strategic enabler for organizations seeking environmental credit value.

How RENU™ System Supports Cap & Trade and Carbon Credit Generation

1. Measurable Landfill Avoidance

Because the RENU System transforms material physically and immediately, manufacturers can easily quantify:

Total tons of side streams diverted from landfill

Percentage conversion into ingredient-grade powder

Reduction in haul-offs, fuel use, and disposal requirements

These metrics support environmental claims, carbon impact assessments, and participation in waste-based carbon credit pathways.

2. Converting Waste into High-Value Ingredients

By producing ingredient-ready powders, companies can:

Create new revenue streams

Offset raw material purchases

Improve supply-chain resilience

Reduce environmental impact while increasing profitability

Circular economy outcomes and carbon benefits reinforce one another.

3. Lower Exposure to Compliance Costs

Manufacturers using all-electric processing equipment may:

Avoid on-site emissions reporting

Avoid natural-gas carbon surcharges and shutdowns

Reduce capital risk tied to future fuel regulations

The RENU System positions companies for long-term regulatory stability.

4. Operational Efficiency & Sustainability Gains

RENU provides additional operational benefits:

Lower hauling and tipping fees

Reduced waste-handling logistics

Improved plant efficiency and sanitation

A cleaner, more integrated waste-to-value workflow

These advantages support both sustainability and bottom-line performance.

A Combined Advantage: Electrification + Circular Production

Many solutions reduce emissions and others reduce waste. But RENU uniquely enables companies to do both by design:

Electrification removes fossil-fuel combustion from the process

Powderization removes landfill dependence and creates ingredient value

This tandem effect strengthens a manufacturer’s position in:

Cap-and-trade states

Carbon offset markets

ESG scoring systems

Circular economy certification pathways

It’s a high-impact approach with measurable environmental and financial benefits.

Real-World Applications in Food Manufacturing

Beverages & Brewing: Transform pulp, spent grains, or plant fiber into nutrient-rich powders PLA fillers and biodegradable packaging.

Fruits & Vegetables: Powderize peels, pulp, stems, and other byproducts into shelf-stable ingredients and natural dyes and colorants.

Nuts and Seeds: Efficiently convert pits, seeds, and nuts into spices and herbs.

In each case, manufacturers reduce waste, generate product value, and support methane-avoidance impact.

Future-Ready by Design

As carbon markets evolve and waste-diversion crediting expands, RENU is positioned to support:

Additional side-stream categories

Advanced waste-to-ingredient valorization

Partnerships with carbon methodologies or third-party verifiers

Integration with electrified manufacturing standards

Manufacturers using RENU are prepared not only for today’s sustainability demands, but for tomorrow’s as well.

Conclusion

GTF’s RENU System helps food manufacturers transform waste into opportunity. By powderizing side streams using clean, all-electric processing, companies can:

Avoid landfill dependence

Reduce regulatory exposure

Unlock carbon and ESG value

Create new revenue streams

Support circular economy leadership

For industries operating in cap-and-trade environments—or simply striving to reduce waste—RENU offers a powerful, future-proof solution.