Technology

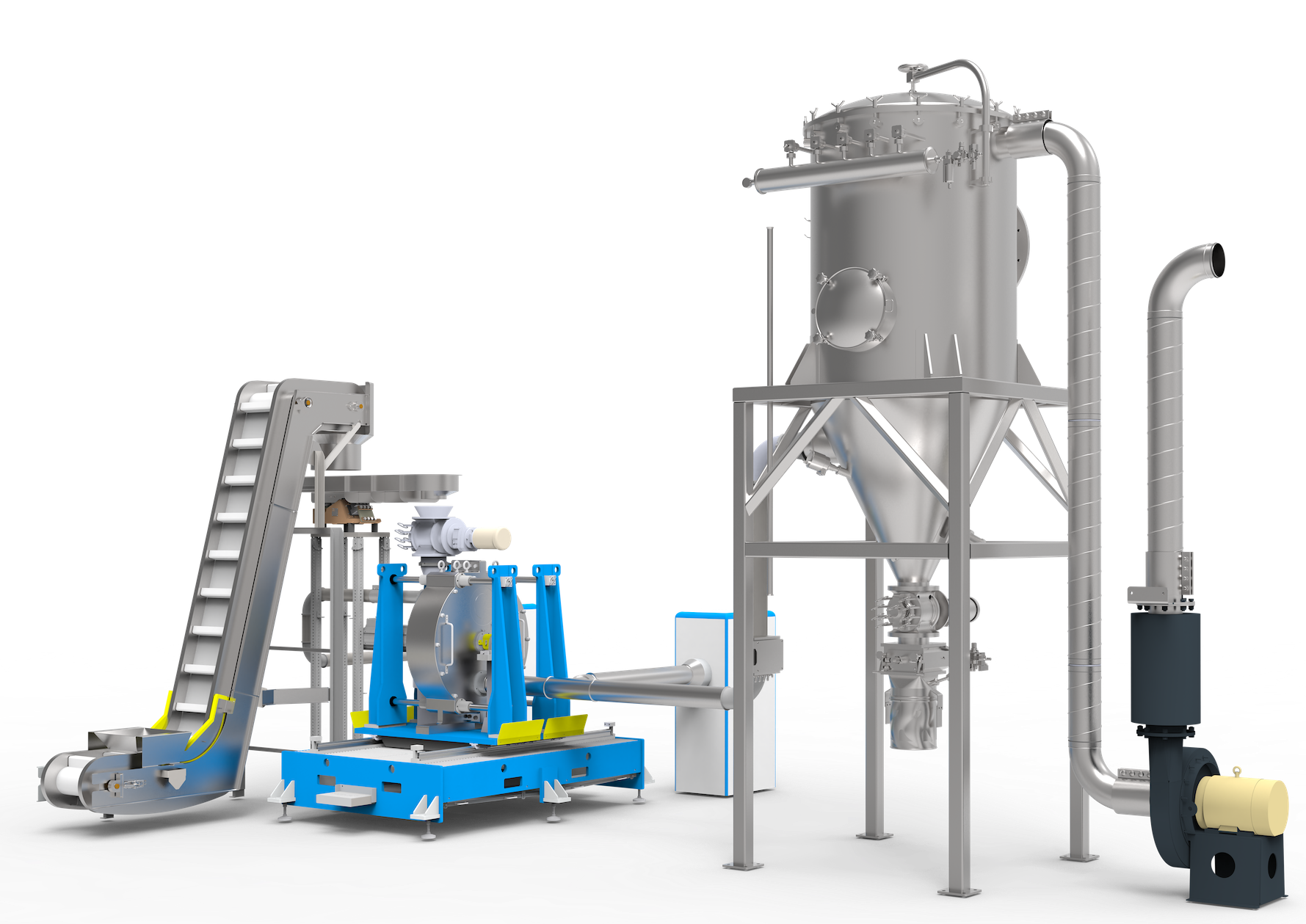

The RENU™ Drying & Milling System

RENU™ (Rapid Extraction, Nutrient Upcycling) dries and mills in one quick step to transform and upcycle raw materials into powder. Because the RENU System processes material quickly without natural gas or extreme temperatures, it is energy efficient and has excellent nutrient retention of the input material. The resulting powders are pure, nutrient-dense, and ready for resale in many applications.

How It Works

Our technology’s six key components work together to create the ideal powder for each product and desired application.

RENU™ System Components

-

Completely customizable, depending on product and conditions; may be designed for inline or batched processes.

-

Complete system control with one-touch interface monitors the output and optimizes system performance; provides Clean-In-Place technology.

-

A single-pass system that conditions incoming air to provide the optimal environment for moisture extraction.

-

Proprietary, revolutionary milling process; simultaneously extracts moisture from raw material and powderizes while retaining nutrients.

-

Allows for controlled separation of extracted moisture from the final powderized product.

-

Fully customizable; may be operated manually or automatically.

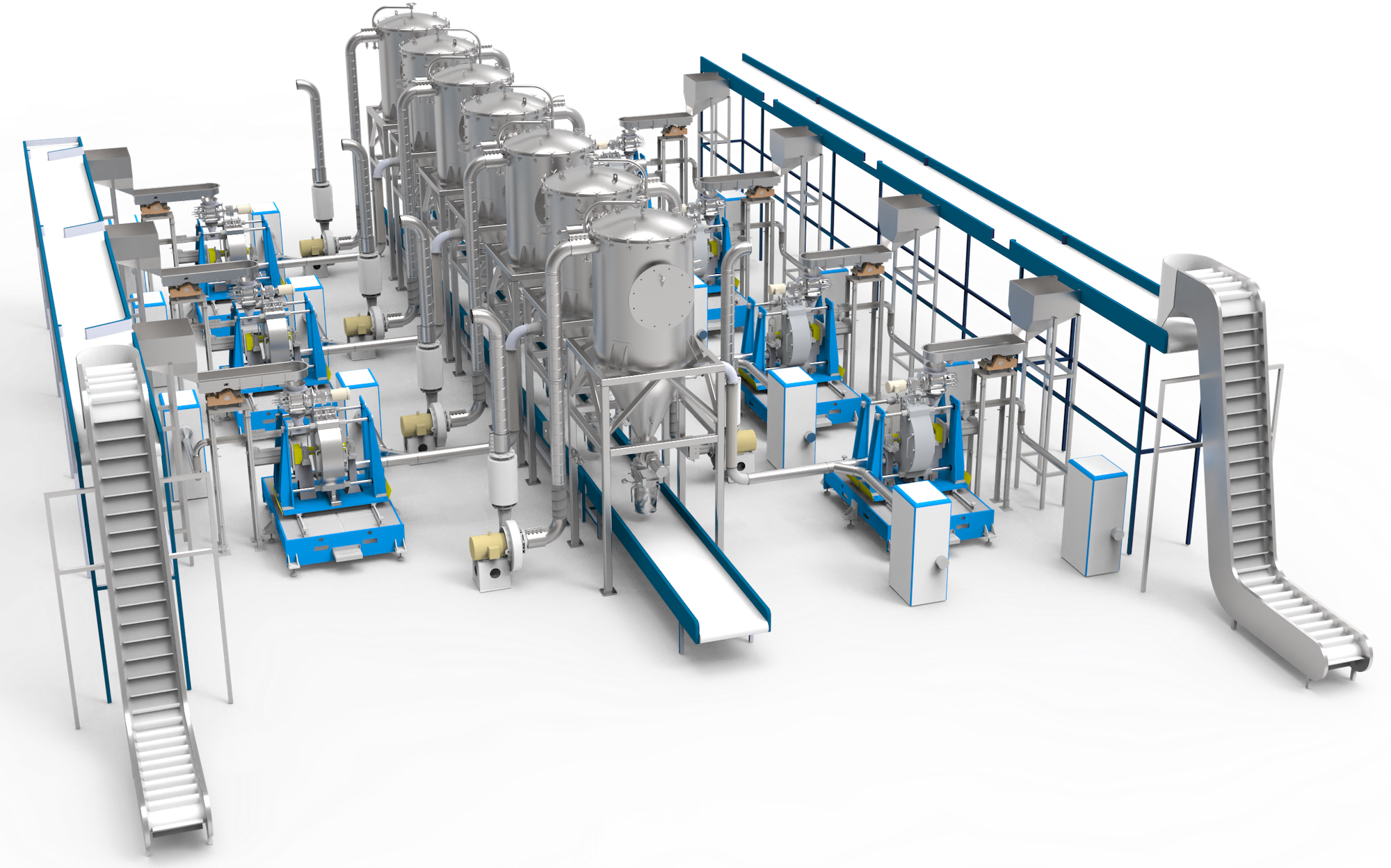

Scalability

RENU™ can easily be joined together for larger installations and batch processing. Here, we show configurations for 1-, 3-, and 7-system installations. We can also design a custom, multi-system installation to fit your facility's requirements.

Key Features

-

Dries and mills simultaneously

-

Powder is created from raw materials in seconds

-

Removes up to 99% of moisture from source material

-

Fully automated cleaning in 30 minutes or less

-

Retains nutrients due to low temperatures and fast processing

-

No natural gas results in low operating costs & eco-friendly manufacturing

-

One-touch controls are configured for your materials and outputs

Production Benefits

-

Occupies less than 1,000 sq. ft. and can scale up to meet larger volume requirements

-

Each system is custom designed to meet your production specifications

-

Upcycle and monetize side streams, byproducts, & excess production

-

Stainless steel supports clean-label, upcycled foods and food-grade facilities

Key Features

2-in-1

Functionality

Dries & mills simultaneously

Fast

Processing

Powder is created from raw materials in seconds

Moisture

Extraction

Removes up to 99% of moisture from source material

Clean-in-Place

Fully automated cleaning in 30 minutes or less

Nutrient

Retention

Retains nutrients due to low temperatures and fast processing

100%

Electric

No natural gas results in low operating costs & eco-friendly manufacturing

P20S

Operating System

One-touch controls are configured for your materials and outputs

Production Benefits

Scalable

Occupies less than 1,000 sq. ft. and can scale up to meet larger volume requirements

Customizable

Each system is custom designed to meet your production specifications

Sustainable

Reduces food waste; upcycles and monetizes side streams, byproducts, & excess production; energy efficient operation

Food Grade

Stainless steel supports clean-label, upcycled foods and food-grade facilities

Alternative to Traditional Drying Methods

Traditional drying methods consume copious amounts of time, square footage, and energy, depending on the method used.

-

Freeze dryers take hours to complete a single cycle, requiring vast amounts of real estate and energy. Then, if powder is the desired end product, dried food must also be milled. In contrast, RENU™ dries and mills in seconds.

-

Spray dryers have high overhead costs due to their immense energy requirements and high maintenance costs. In addition, their extreme operating temperatures degrade vital nutrients. Because RENU™ does not “cook” materials and uses no external heat or gas, it has excellent nutrient retention.

-

The high temperatures required in drum drying reduce food’s sensory profiles are compromised. RENU's™ low run temperatures and high speed of operation result in powders with excellent color, flavor, aroma, and nutrient retention.

-

Hammermills have high power requirements and do not dry food, so they are best used for grains and previously dried foods. RENU™ dries and mills concurrently in a single step. It transforms foods with up to 99% moisture to powders with as low as 1% moisture in seconds.

Benefits of Powderizing Side Streams

Boost Your Bottom Line

Instead of paying to landfill excess materials or making pennies on the dollar for livestock feed, transform your waste into a new profit center by powderizing and upcycling your side streams.

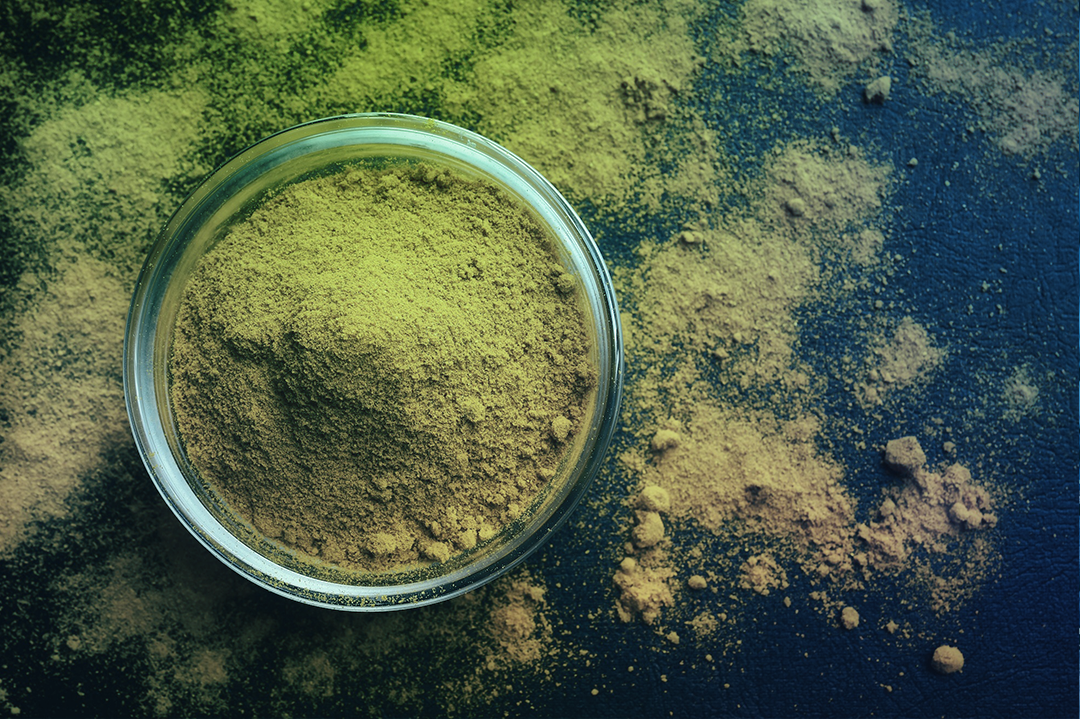

Create Valuable Powders

The powdered dietary supplements market is valued at $35.9 billion—and growing. Fruit and vegetable powders contain polyphenols and antioxidants, retailing for up to $50/lb. Powders are also used as natural ingredients in foods and beverages, pet foods, beauty products, plant-based proteins, or natural fabric dyes.

Reduce Waste, Improve Sustainability

Rescue your side streams from landfills and achieve your corporate sustainability goals. Reduce our collective carbon footprint and make a positive impact on the environment.

Contribute to the Upcycled Food Market

Upcycled foods create new, high-quality products from surplus foods. Powdered side streams are perfect as nutritious ingredients in upcycled foods. Whole Foods Market named upcycled foods one of the top 10 food trends of 2021, and the upcycled food market is worth $52.9 billion and growing.

Feed People

GTF-milled powders are shelf-stable and nutrient-dense. Our powders can be reconstituted and mixed with indigenous foods to fill bellies and improve nutrition in food deserts and famine-impacted areas. GTF has formed a non-profit to use excess powders to feed hungry people around the world.

Benefits for GTF Powder Customers

The powders generated by our RENU™ System can be used in many products:

Vitamins

Supplements

Nutraceuticals

Upcycled Foods

Beverages & Sports Drinks

Food Ingredients

Spices

Pet Foods

Biomaterials

Biofertilizers

Why GTF powders are superior to what’s currently on the market:

We can powderize virtually any plant material.

To discover the GTF difference, contact us for a powder sample and/or nutritional information about a specific product.